Over the course of a CRIN-supported project, Ekona Power Inc.’s methane pyrolysis technology evolved from a small “proof of concept” innovation to an operational, field-deployable reactor that significantly reduces CO2 emissions compared to traditional methane reforming processes.

The project, Pilot Deployment of Ekona’s PMP Solution for Clean Hydrogen Production, enabled Ekona to grow its team, develop important IP, and advance its technology.

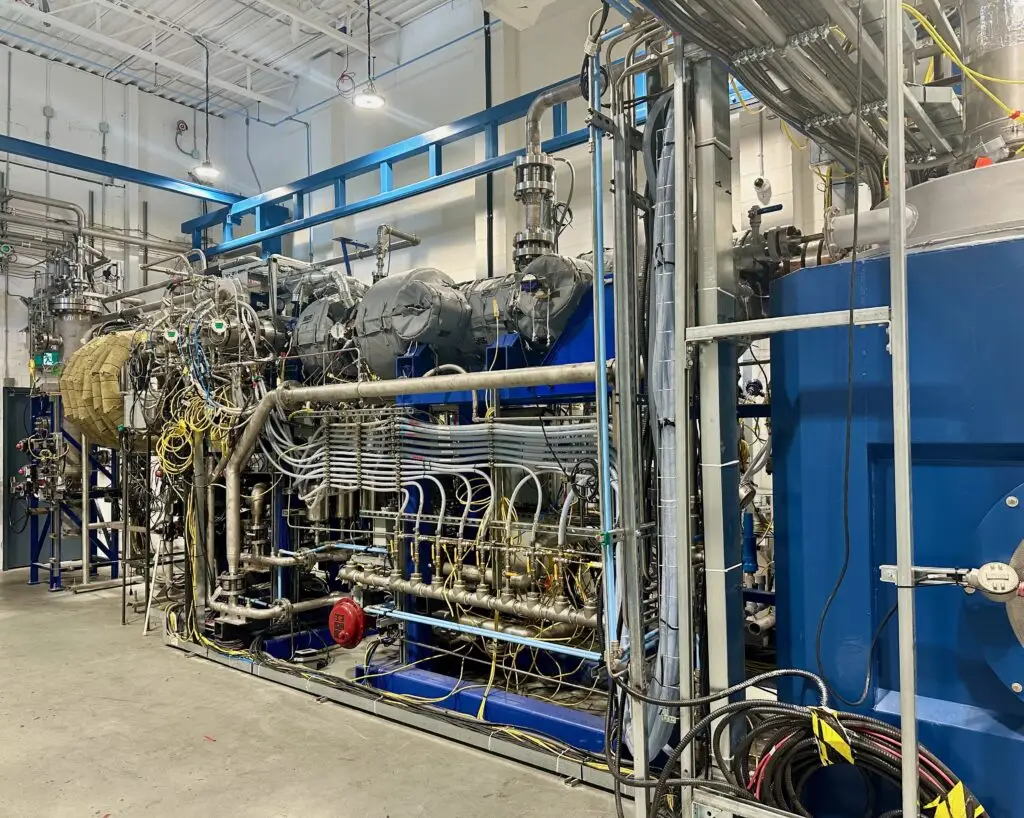

Gary Schubak, Chief Commercial Officer at Ekona Power, said that with the support of CRIN and other partners, Ekona built a 200-kilogram-per-day pilot facility in Burnaby where they test and develop reactors and produce clean hydrogen and clean carbon black.

“We’re presently in the process of scaling up the pilot to half a ton of hydrogen per day with our next-generation reactor,” he said in an interview.

The CRIN-supported initiative was a “pivotal program” for Ekona to scale its first-generation reactor, bring the technology up to capacity, and integrate it with the systems used in a methane pyrolysis facility, he said.

Ekona’s innovative methane pyrolysis technology transforms natural gas into hydrogen and solid carbon. The company’s unique xCaliber™ reactor uses combustion to dissociate methane feedstock. This low-cost, scalable solution integrates seamlessly with industry-standard balance-of-plant equipment for hydrogen purification and carbon separation, simplifying industrial adoption.

“Ekona’s technology builds on existing natural gas infrastructure,” Schubak said.

“One of the things that’s held back hydrogen technology and fuel cell technology is infrastructure. Building out this hydrogen infrastructure to get hydrogen to industry, into communities, is a massive task. We’ve got this wonderful natural gas backbone built across our country, across our continent and globally, and our technology just sits on that infrastructure. We take natural gas and we break it into two usable products, hydrogen and carbon, where it’s needed, and we can start to deploy hydrogen technology with industry without needing to address the infrastructure.”

Methane pyrolysis also offers a technology pathway that can decarbonize the production of hydrogen while maintaining existing cost structures, by monetizing the co-product, clean carbon black.

“Monetizing carbon black drives the economics of hydrogen production in a favourable way, and that’s the game-changing component that methane pyrolysis and Ekona’s technology provides,” Schubak said.

Markets for clean carbon black, a fine black powder, include tires and rubber, plastics, battery electrodes, asphalt, cement and construction materials, soil remediation, and water purification.

The team at Ekona is now focused on integrating its second-generation reactor technology and scaling up the Burnaby pilot to operate as a 24/7 hydrogen and carbon black production demonstration facility. This will provide industry partners with firsthand visibility into commercial-scale operation and serve as a platform to advance off-take engagement.

Amid the current expansion, Ekona credits the CRIN funding they received as crucial to getting their pilot facility up and running in Burnaby.

“I want to thank CRIN once again for being such a good partner,” said Schubak.

You can learn more about Ekona and their latest news on their website.

To read more innovation stories from CRIN’s previous technology competitions, visit our Stories page. To learn more about CRIN’s new technology competition, open until February 26, 2026, click here.